Regarding our titanium wire products

Our titanium wire is mainly used in the fields of aviation, aerospace, medical, welding, and 3D printing. A globally renowned brand of titanium alloy additive materials.

Application fields of titanium wire:

Straight wire products welding, medical, aviation Roller products 3D printing, medical, aviation, welding Circular products 3D printing, industrial, medical, aviation Characteristics of titanium wire for welding: Bright surface, smooth wire feeding during MIG welding. For special application markets, we can conduct targeted research, experimentation, and development:

We have developed a new titanium alloy wire processing technology that can quickly improve efficiency and reduce costs by 20%.

The new smelting equipment has improved the high-tech capabilities of titanium alloy smelting, which can reduce the smelting cost of titanium alloy by 10-15%.

The development project of a new experimental melting equipment with a weight of 300-500kg for specialized titanium alloys can be successfully carried out using our 5-ton furnace for mass production.

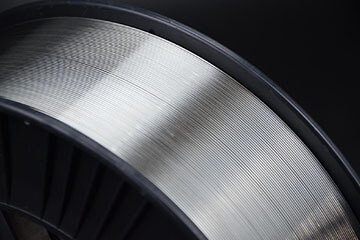

Features of titanium wire products:

Size 0.8-6.35mm Specifications AWS A5.16, ASTM B863/ASTM B348,ASTM F136, ASTM F67, AMS 4954, AMS 4951, AMS 4956, MSRR 9500/70, MSRR 9500/73, UNS R50550, UNS R56400, DIN 3.7035, DIN 3.7165 Material 6AL4V ELI, CP Ti, ERTi-1, ERTi-2, ERTi-3, ERTi-4, ERTi-5, ERTi-7, ERTi-9, ERTi-12, ERTi-23Grade 1,Grade 2,Grade 3,Grade 4,Grade 5,Grade 7,Grade 9,Grade 12,Grade 23 Type Titanium Straight wires, length: 1000mm & 914mm Titanium wires in coil, Titanium wires in spool.D600, D300 ; D100 spool Surface Pickling, Ground, Polished : Peeled : Weight each 5kgs each plastic box for straight wires : 7-11kgs for each spool : 30-120kgs for each coil

Military applications, self-developed application brand:

TC4-AH, TTS-4954-21007 Rev.1,TTS-TC4 SLO-20005 Rev.2, TTS-64MO-21002 Rev.2, Ti-5AL-2Mo-2Zr-1.5Sn-1Cr-1V

Welding materials for weapons and tanks:

TC4,TC3, TC1

Materials for weapon additives:

TC4, TA15, TC11

Features:

Smooth and efficient wire feeding.

The surface is smooth and the smoothness meets the requirements of aviation grade.

The material strength can be customized for melting according to needs, with good elasticity resistance and welding toughness.

Location:

Location: