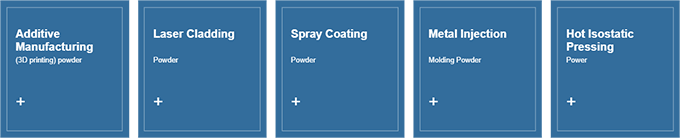

About our powder raw materials

Relying on our R&D team’s more than ten years of dedicated research on materials, We has developed a series of alloy powder materials for aerospace, digital healthcare, automotive manufacturing, consumer electronics, industrial molding and other applications. With high purity and sphericity, low oxygen content and excellent performance, our products are widely applied in selective laser melting (SLM), laser solid forming (LSF), laser cladding (LC), metal injection molding (MIM), hot isostatic pressing (HIP) and other manufacturing techniques.

Advanced atomization powder making technology:

We have thus made a breakthrough in world-leading powder production technology, such as Vacuum Induction Inert Gas Atomization (VIGA), Electrode Induction Gas Atomization (EIGA), Plasma Rotary Electrode Atomization (PREP), Plasma Atomization (PA), etc.,

| VIGA/GA |

| Vacuum/non-vacuum refining ensures the purity of alloy liquid and good alloying condition ▪ The fast solidified powder, with high sphericity, exists in supersaturated solid solution, its elements slightly segregated or non-segregated. ▪ With adjustable capacity, the furnace has a relatively low cost, suitable for research and mass production. |

| Applied Materials |

| ▪ Nickel Alloy, Cocr Alloy, Stainless Steel, Aluminum Alloy, Ferrous Alloy, etc. Size Distribution: 0-150μm; Nickel Alloy Powder D50: 20-60μm |

| EIGA |

| ▪ Pollution-free: non-contact melting without crucible ▪ Minimal burning loss of constituent elements; flexible alloy bar size ▪ Flexible feeding capacity for both research and mass production |

| Applied Materials |

| ▪ Ti, Titanium Alloy, Ti-Al, Ni-Ti Shape Memory Alloy Size Distribution: 0-150μm |

| PA |

| ▪ High yield of fine powder ▪ Low cost of gas ▪ Good quality stability of each batch for both scientific research and batch production |

| Applied Materials |

| ▪ Ti, Titanium Alloy, Nickel Alloy, Ni-Ti Shape Memory Alloy Size Distribution: 0-150μm |

| PREP |

| ▪ High-sphericity droplet atomization realized by centrifugal force mechanism ▪ Low production cost ▪ Flexible feeding capacity for both research and mass production |

| Applied Materials |

| ▪ Ti, Titanium Alloy, Nickel Alloy, Cocr Alloy, Ferrous Alloy, etc. Size Distribution: 30-300μm |

which two technologies, VIGA and EIGA, are the first to realize domestication. The high-end powder materials dedicated for 3D printing developed by us, such as titanium alloy and superalloy, have been applied and industrialized in the national defense equipment.

Location:

Location: