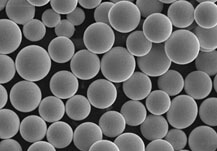

In738LC Powder product details:

| main products | In738LC | |||

| Main grain size range | 0-25 μm | 15-53 μm | 45-105 μm | 75-150 μm |

| mobility | 15-53μm | ≤16s/50g | ||

| Bulk density | ≥4.60g/cm3 | |||

| oxygen content | ≤200ppm | |||

| nitrogen content | ≤200ppm | |||

| mechanical property | compressive strength /Mpa 1000±50 | |||

| yield strength /Mpa 900±50 | ||||

| Elongation /% 13±2 | ||||

IN738LC (K438) is a nickel based precipitation hardening equiaxed crystal cast high-temperature alloy, which is one of the alloys with the best thermal corrosion resistance. When used at temperatures below 900 ℃, cobalt, chromium, and molybdenum elements are added to the alloy for solid solution strengthening, aluminum and titanium elements are added to form a phase, and boron and zirconium elements are added to purify and strengthen grain boundaries. This alloy has excellent resistance to hot corrosion, moderate high temperature strength, and good structural stability. It is used for long-life turbine blades and guide vanes in ships and ground industrial gas turbines, as well as turbine parts and corrosion-resistant components in aircraft engines.

Location:

Location: